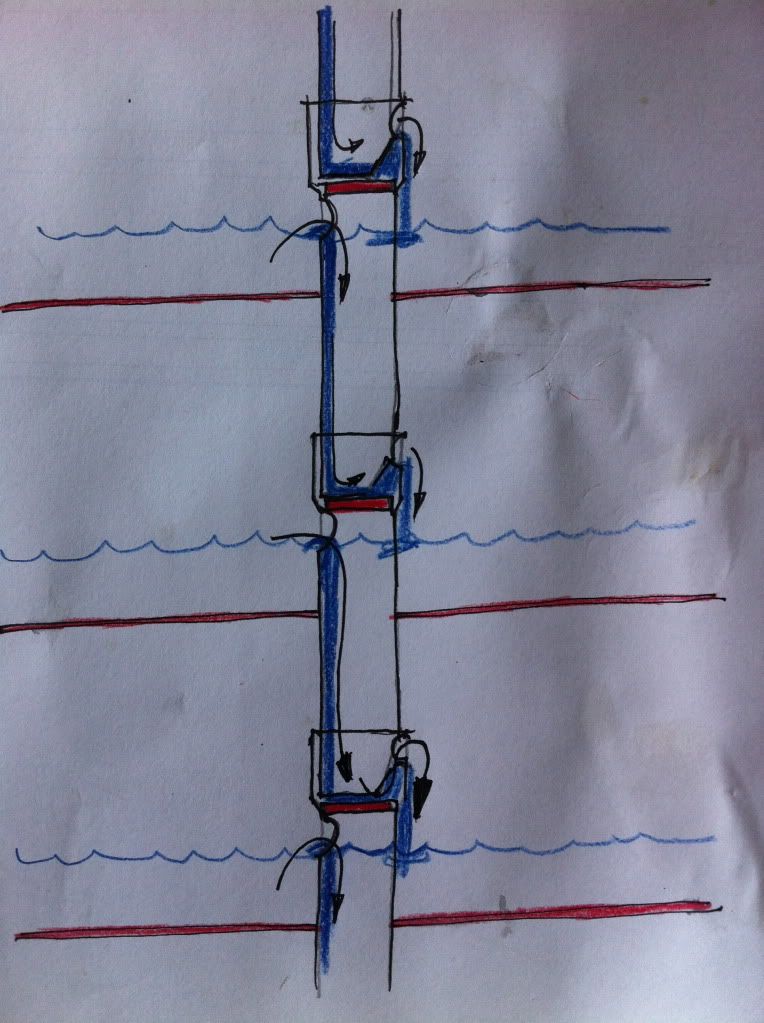

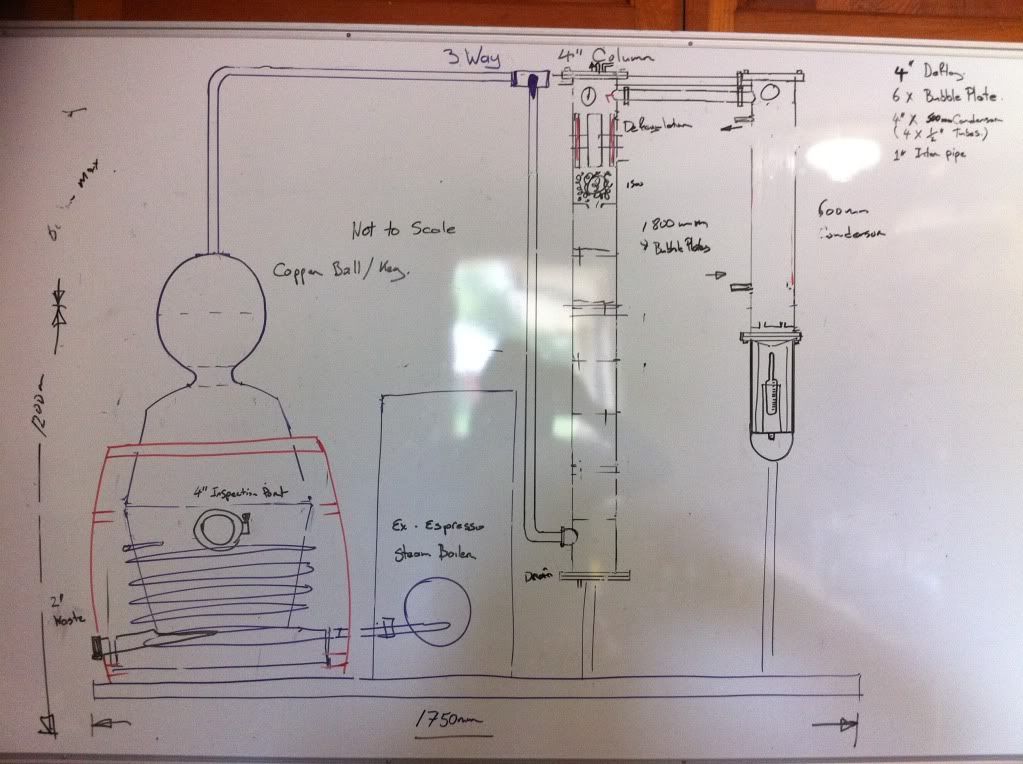

What I have drawn is a designed to be a dual purpose rig.

I wanted a copper pot boiler with the option of running straight to the condenser on the right via a three-way ball valve. With just the ball to give a bit of reflux.

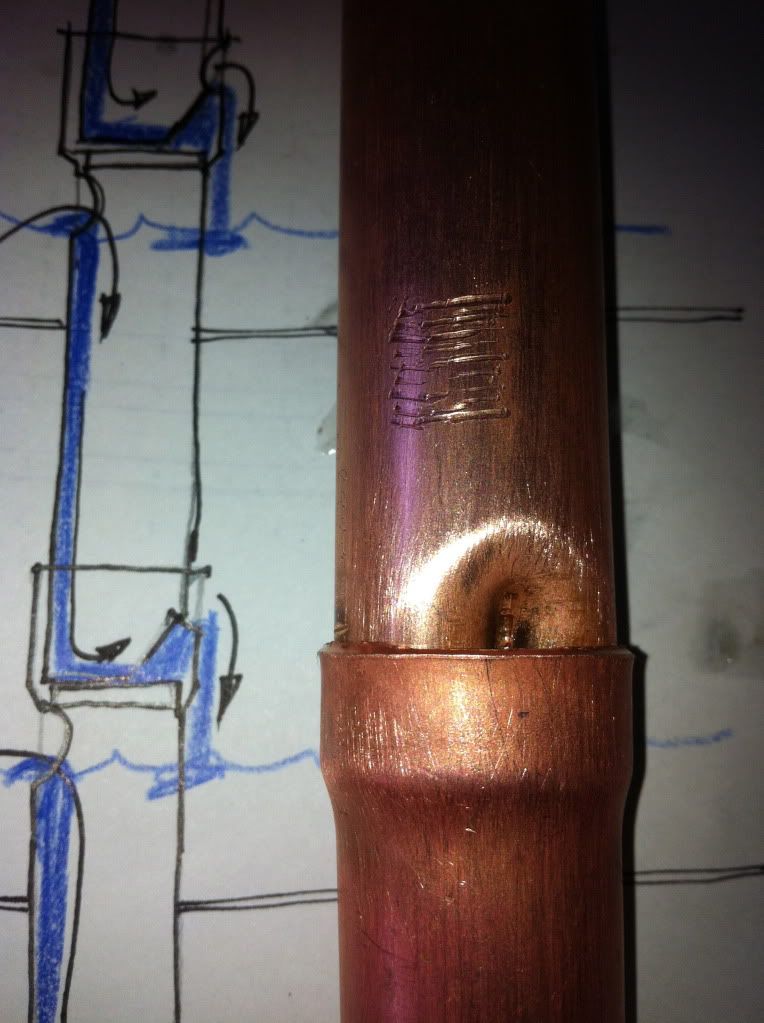

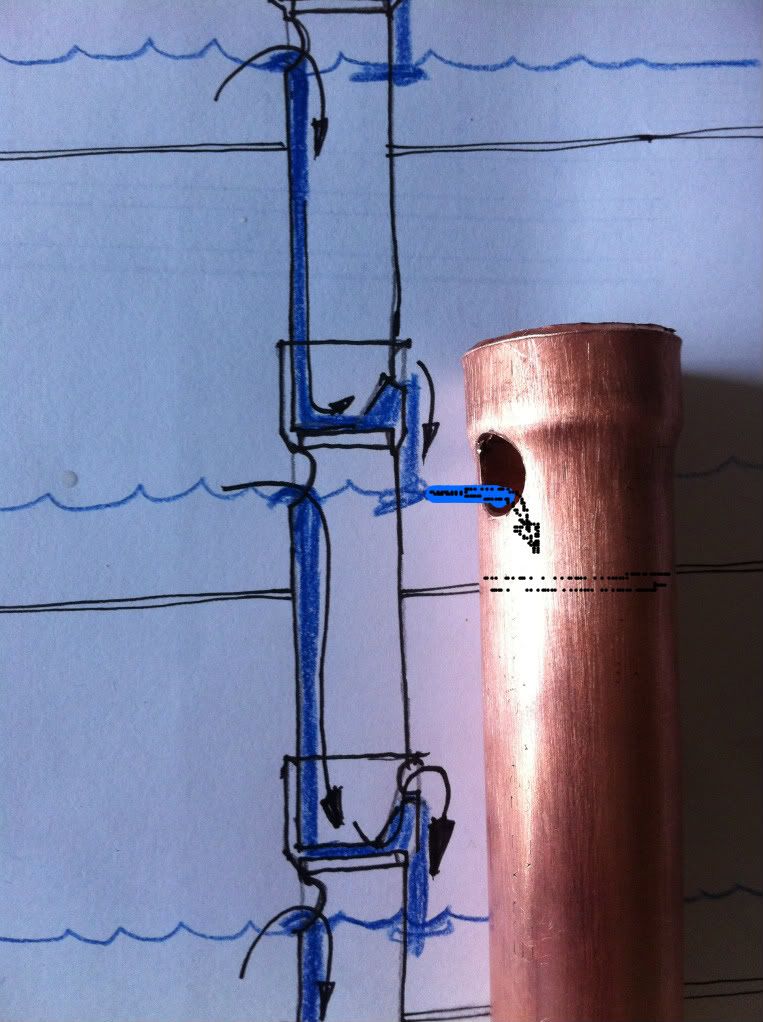

I have a 1800mm length of 4" copper so i am thinking that the column will be plated with a "Mac" sized reflux condenser sitting a top. Side inlet & outlets to save on height.

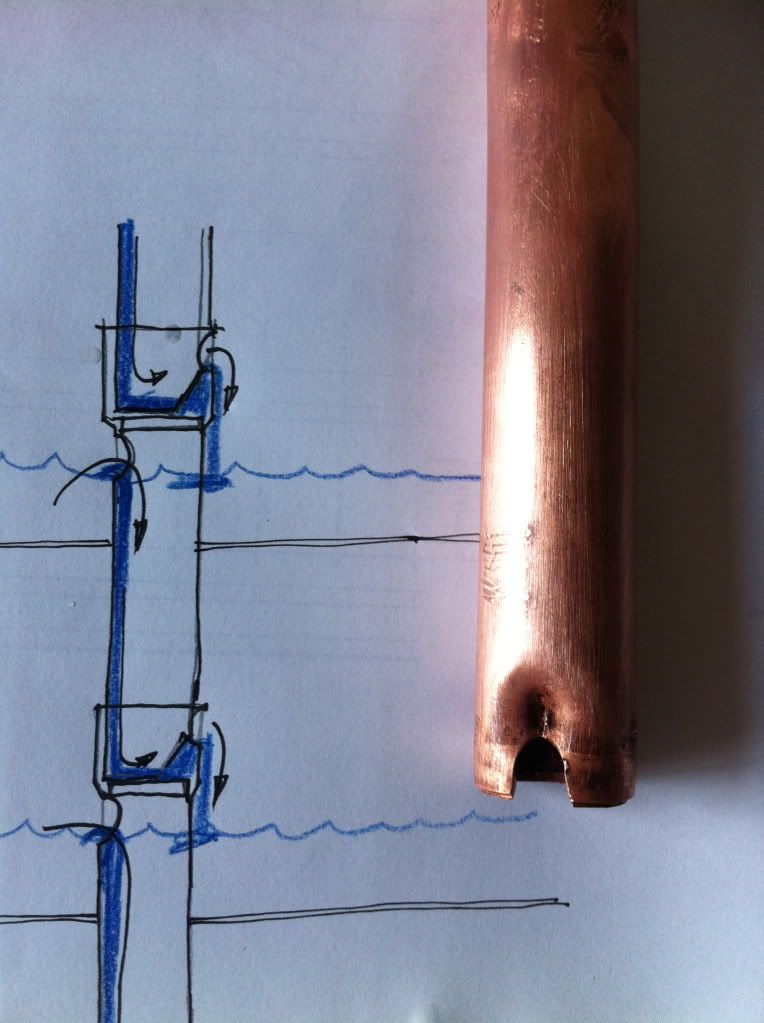

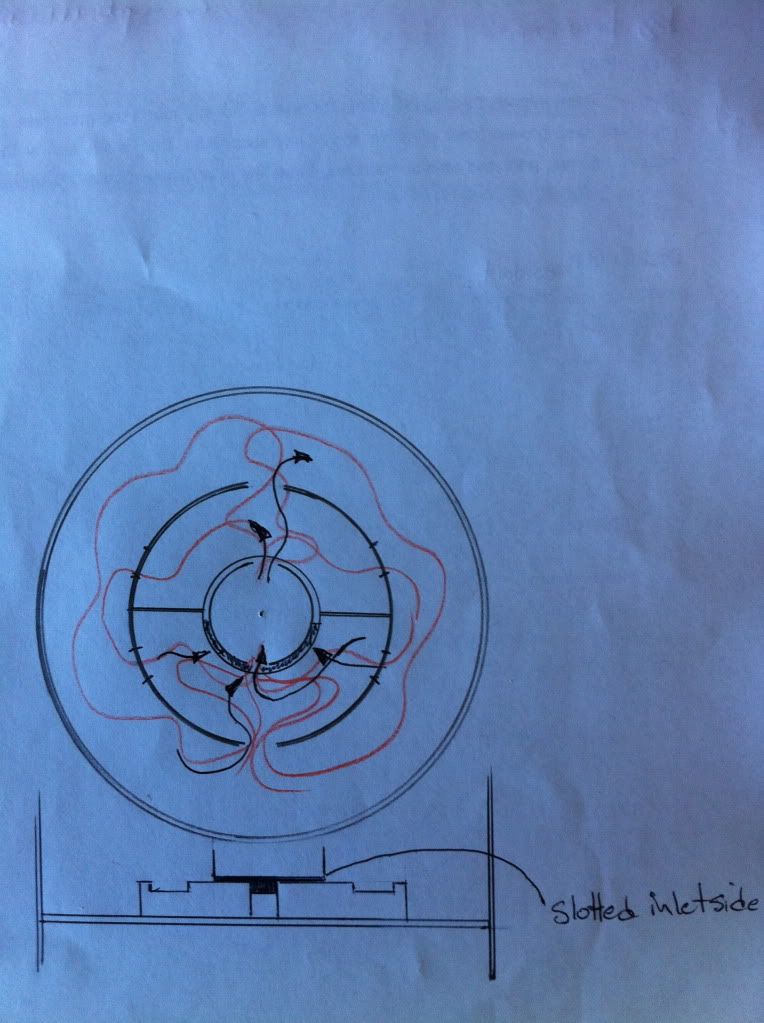

Number of plates to be decided. But I am thinking as many as possible given the 1800mm length. Plates will be bubble or the poppet valve idea I have posted earlier.

Connecting pipes? maybe 1" to keep the product velocity up.

The copper washing tubs are going top and bottom of the boiler.

2" waste drain & a 4" inspection port so I can get my arm in.

The heating plan is to use steam. The steam supply is based on ex-espresso machine boilers with 1/4" copper pipe soldered to the insulated outside of the bottom boiler and a single internal coiled 1" copper heating tube fed from a separate espresso boiler. ( have access to a couple of these)

5 Star Store

5 Star Store Community Guidelines

Community Guidelines Newbies Corner

Newbies Corner Recipes

Recipes AD search

AD search