Reflux / Pot still

30 posts

• Page 1 of 2 • 1, 2

Reflux / Pot still

I have a reflux still with a 1m x 2" column and a Liebig condenser. It makes a pretty good neutral from TPW if I run it nice and slow and I'm happy with that. I use stainelss steel pot scrubbers in the column as they are cheap and easy to source. I make a reasonable brandy using Prestige essence and a toasted French oak chip recipe that the wife prefers to most commercial brandys. Myself, I like rum and bourbon but have yet to hit on anything I like as much as some of the shop bought spirits.

Recently, disappointed with the various rum essences, I tried a molasses rum wash and ran my still minus the scrubbers, and with no water running through the condenser. Using the gas jet, I tried to keep the temp at around the 80C and collected about 300ml (after disposing of 150ml foreshots). This 300ml was very aromatic and had a great molasses type nose but it was obvious that I was losing a lot straight into the atmosphere. So I started running water through the condenser as slowly as I could and collected the rest of the spirit like that. It has a small molasses nose to it but nothing like the first 300ml. I guess even with a small amount of water flow i am getting too much reflux and losing the taste I want.

So, my idea, rather than lashing out and building a pot still (which I will do eventually no doubt) straight away is......to build a small condenser to attach to the output of my current setup. So running it as before with no cooling, but pushing the vapours through the new condenser (but of course no cooling going through the column) and collecting the resulting spirit from that......so I guess converting the reflux into an adhoc pot still.

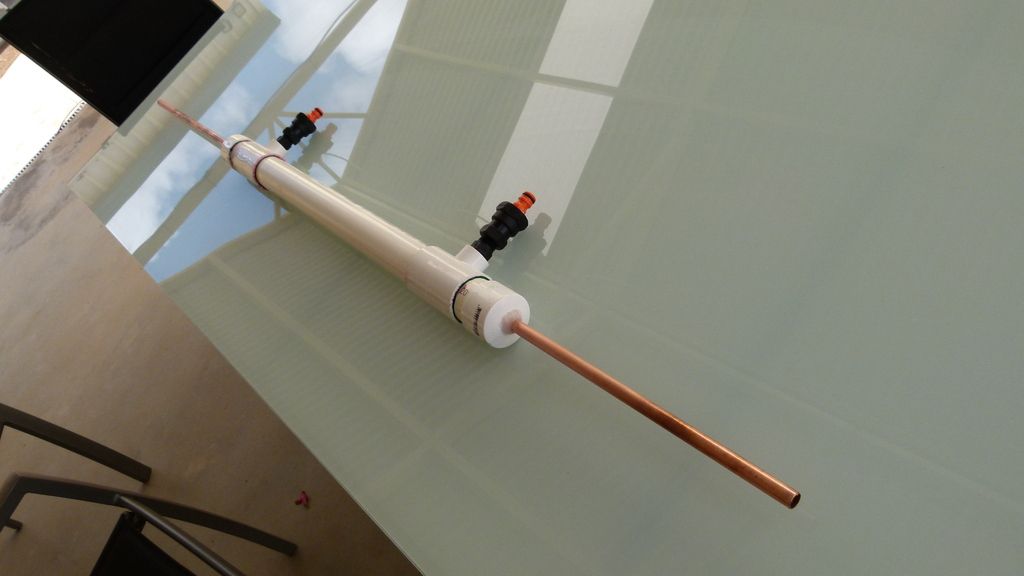

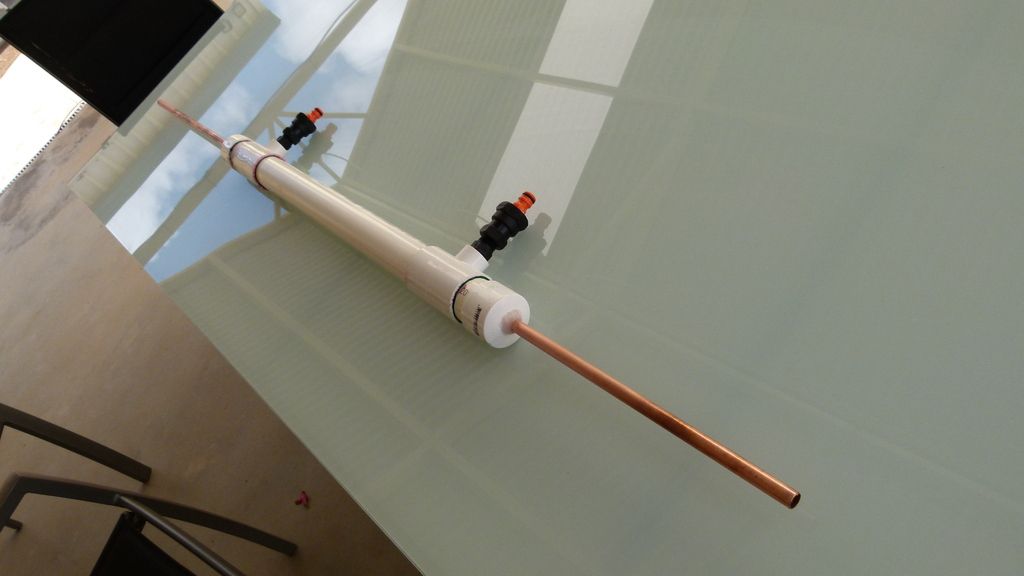

I've just about got it done now with about 600mm of 12mm copper tubing going through about 500mm of a 4omm PVC jacket.

So can any of you more experienced distillers tell me if I am sort of on a track that will give me the rum taste that I'm looking for?

Recently, disappointed with the various rum essences, I tried a molasses rum wash and ran my still minus the scrubbers, and with no water running through the condenser. Using the gas jet, I tried to keep the temp at around the 80C and collected about 300ml (after disposing of 150ml foreshots). This 300ml was very aromatic and had a great molasses type nose but it was obvious that I was losing a lot straight into the atmosphere. So I started running water through the condenser as slowly as I could and collected the rest of the spirit like that. It has a small molasses nose to it but nothing like the first 300ml. I guess even with a small amount of water flow i am getting too much reflux and losing the taste I want.

So, my idea, rather than lashing out and building a pot still (which I will do eventually no doubt) straight away is......to build a small condenser to attach to the output of my current setup. So running it as before with no cooling, but pushing the vapours through the new condenser (but of course no cooling going through the column) and collecting the resulting spirit from that......so I guess converting the reflux into an adhoc pot still.

I've just about got it done now with about 600mm of 12mm copper tubing going through about 500mm of a 4omm PVC jacket.

So can any of you more experienced distillers tell me if I am sort of on a track that will give me the rum taste that I'm looking for?

- toadskin

- Posts: 41

- Joined: Sat Dec 01, 2012 1:22 pm

- Location: Geraldton WA

- equipment: Home made Reflux still with Liebig condenser and a home made 2" Pot Still with Liebig.

Re: Reflux / Pot still

Sounds like it will work mate, a couple of pics will help us work out what you've got going on though :handgestures-thumbupleft:

- Zak Griffin

- Lifetime Member

- Posts: 6832

- Joined: Mon Jul 15, 2013 9:34 pm

- Location: Radelaide

- equipment: "The Heart of Gold" - 4" Bubbler - finally bubbling!

"Zaphod" - 3" Pot - retired

"Agrajag" - 6" Bubbler - midlife crisis build?

Re: Reflux / Pot still

Couple things, you are likely to cause an explosion if you run with out water running through the pc.

The mod you are proposing sounds like it'll take care of that but it could cause further problems if your reflux jacket is made from plastic. As it could melt or turn brittle and crack.

In order to get a good spirit running the way you describe your going to need an element power controller to be able to slow down the take off. As the water flow isn't able to do this.

A few pics will definitely help

The mod you are proposing sounds like it'll take care of that but it could cause further problems if your reflux jacket is made from plastic. As it could melt or turn brittle and crack.

In order to get a good spirit running the way you describe your going to need an element power controller to be able to slow down the take off. As the water flow isn't able to do this.

A few pics will definitely help

- coffe addict

- Posts: 1027

- Joined: Thu Feb 26, 2015 12:00 pm

- Location: Brisbane central

- equipment: 18 gal keg boiler on its side on wheel's with fill port, 1in drain and 2x2.4kw elements

4in 5 plate modular blockhead with optional infusion basket

Re: Reflux / Pot still

Trying to visualize your setup. Is it a cm still? How do you run without your liebig or is the product condenser simply overwhelmed?

- warramungas

- Posts: 1436

- Joined: Sun Oct 18, 2015 9:38 pm

- Location: Nor Perth

- equipment: 180 litre fermenter x 2

30 liter boiler

PDA-1

2" four plate modular bubbler

2" one meter long LM column

110 liter boiler with 25 liter (max) inline thumper

4" x 4 plate bubble cap still

Re: Reflux / Pot still

coffe adict: The PVC jacket will have water from my rainwater tank running through it so it won't get hot. The new condenser will be attached directly to the outlet of the Liebig.

Warramunga: Yes, it's a CM still. I'll run it without any water going through the liebig as I'm getting too much reflux in the column. The new condenser will attach to the outlet of the liebig and condense the vapours thus avoiding the cooling that occurs in the column when I have the liebig running.

I'm working on getting an element for my keg. Just need to find someone local to do some TIG work for me and then I'll go ahead and source the parts.

I'll post some photos when I get the condenser finished.

Warramunga: Yes, it's a CM still. I'll run it without any water going through the liebig as I'm getting too much reflux in the column. The new condenser will attach to the outlet of the liebig and condense the vapours thus avoiding the cooling that occurs in the column when I have the liebig running.

I'm working on getting an element for my keg. Just need to find someone local to do some TIG work for me and then I'll go ahead and source the parts.

I'll post some photos when I get the condenser finished.

- toadskin

- Posts: 41

- Joined: Sat Dec 01, 2012 1:22 pm

- Location: Geraldton WA

- equipment: Home made Reflux still with Liebig condenser and a home made 2" Pot Still with Liebig.

Re: Reflux / Pot still

If its a CM you should/might be able to separate the reflux condenser from the product condenser...

- Zak Griffin

- Lifetime Member

- Posts: 6832

- Joined: Mon Jul 15, 2013 9:34 pm

- Location: Radelaide

- equipment: "The Heart of Gold" - 4" Bubbler - finally bubbling!

"Zaphod" - 3" Pot - retired

"Agrajag" - 6" Bubbler - midlife crisis build?

Re: Reflux / Pot still

Sounds like you should just open the outlet valve and run the PC flat out.

Anything that is condensed will exit the still via the outlet as liquid instead of into the atmosphere as vapour.

Anything that is condensed will exit the still via the outlet as liquid instead of into the atmosphere as vapour.

- scythe

- Posts: 1860

- Joined: Thu Nov 14, 2013 6:34 am

- Location: Central West NSW

- equipment: Dreaming of a 4" bubbler

Re: Reflux / Pot still

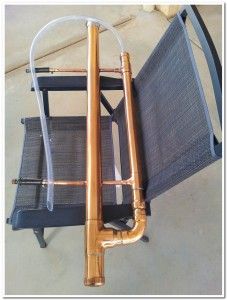

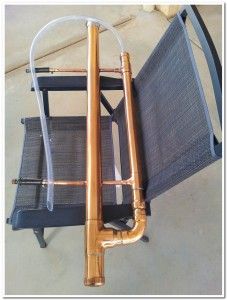

I guess I could alter it so that I could run it as a full reflux or as a pot still. Definitely worth giving it some thought. In the mean time I have come up with this so I'll give it a run and see how it works (or not)

my original still....lost the silicon hose.

my original still....lost the silicon hose.

my temporary condenser

my temporary condenser

my original still....lost the silicon hose.

my original still....lost the silicon hose. my temporary condenser

my temporary condenser- toadskin

- Posts: 41

- Joined: Sat Dec 01, 2012 1:22 pm

- Location: Geraldton WA

- equipment: Home made Reflux still with Liebig condenser and a home made 2" Pot Still with Liebig.

Re: Reflux / Pot still

What I'd do with that still is solder up the hole in the top to the thermometer and cut the cooling pipes between the column and PC, and use it as a designated pot still.

Attach your cooling lines straight to the product condenser (water in at the bottom), voila; pot still :handgestures-thumbupleft:

Attach your cooling lines straight to the product condenser (water in at the bottom), voila; pot still :handgestures-thumbupleft:

- Zak Griffin

- Lifetime Member

- Posts: 6832

- Joined: Mon Jul 15, 2013 9:34 pm

- Location: Radelaide

- equipment: "The Heart of Gold" - 4" Bubbler - finally bubbling!

"Zaphod" - 3" Pot - retired

"Agrajag" - 6" Bubbler - midlife crisis build?

Re: Reflux / Pot still

There must be some good voodoo going on inside that copper pipe, i cannot for the life of me comprehend how two bits of 1/2" copper pipe can hold back all the vapours.

I would just build another still to suit what you want to do.

I would just build another still to suit what you want to do.

- scythe

- Posts: 1860

- Joined: Thu Nov 14, 2013 6:34 am

- Location: Central West NSW

- equipment: Dreaming of a 4" bubbler

Re: Reflux / Pot still

I'm a bit confused about that as well, scythe. Makes my 4"x 120mm RC look like a big old WOFTAM!

- Zak Griffin

- Lifetime Member

- Posts: 6832

- Joined: Mon Jul 15, 2013 9:34 pm

- Location: Radelaide

- equipment: "The Heart of Gold" - 4" Bubbler - finally bubbling!

"Zaphod" - 3" Pot - retired

"Agrajag" - 6" Bubbler - midlife crisis build?

Re: Reflux / Pot still

I'm a bit concerned. Unless I'm missing the reflux condenser what you have there is a pot still and running without water is a certain bomb.

One set of cooling lines on the down ward path. Pot still and should be run with enough water to keep the product cool.

To control flow you will need a power controller.

One set of cooling lines on the down ward path. Pot still and should be run with enough water to keep the product cool.

To control flow you will need a power controller.

- coffe addict

- Posts: 1027

- Joined: Thu Feb 26, 2015 12:00 pm

- Location: Brisbane central

- equipment: 18 gal keg boiler on its side on wheel's with fill port, 1in drain and 2x2.4kw elements

4in 5 plate modular blockhead with optional infusion basket

Re: Reflux / Pot still

I was thinking along the same lines Zak. Thought I might put some two way taps between the column condenser and the product condenser so I could use it either way. In the mean time, I'll give this a try and see what I get. I still want to be able to produce a good neutral when I need it.

Don't get what you mean Scythe. The copper runs right through the PVC jacket....720mm of it.

I'm making up connections to the outlet of the liebig and a frame now to hold the condenser at about a 20 deg tilt. I'll post a photo once it's done.

My second wash is well under way so hopefully I'll give it a run this weekend.

Don't get what you mean Scythe. The copper runs right through the PVC jacket....720mm of it.

I'm making up connections to the outlet of the liebig and a frame now to hold the condenser at about a 20 deg tilt. I'll post a photo once it's done.

My second wash is well under way so hopefully I'll give it a run this weekend.

- toadskin

- Posts: 41

- Joined: Sat Dec 01, 2012 1:22 pm

- Location: Geraldton WA

- equipment: Home made Reflux still with Liebig condenser and a home made 2" Pot Still with Liebig.

Re: Reflux / Pot still

I'm not seeing a rc in this please explain where it is.

- coffe addict

- Posts: 1027

- Joined: Thu Feb 26, 2015 12:00 pm

- Location: Brisbane central

- equipment: 18 gal keg boiler on its side on wheel's with fill port, 1in drain and 2x2.4kw elements

4in 5 plate modular blockhead with optional infusion basket

Re: Reflux / Pot still

If the cooling lines go straight through the column they won't be knocking back much at all and cutting flow rates will leave vapour escaping.

- coffe addict

- Posts: 1027

- Joined: Thu Feb 26, 2015 12:00 pm

- Location: Brisbane central

- equipment: 18 gal keg boiler on its side on wheel's with fill port, 1in drain and 2x2.4kw elements

4in 5 plate modular blockhead with optional infusion basket

Re: Reflux / Pot still

The 'RC' is the two 1/2" copper lines running through the column.

- Zak Griffin

- Lifetime Member

- Posts: 6832

- Joined: Mon Jul 15, 2013 9:34 pm

- Location: Radelaide

- equipment: "The Heart of Gold" - 4" Bubbler - finally bubbling!

"Zaphod" - 3" Pot - retired

"Agrajag" - 6" Bubbler - midlife crisis build?

Re: Reflux / Pot still

Then cutting water flow is very dangerous.

Adding a lieberg will make no difference if the water flow is insufficient. It's basically a pot still with a very small amount of reflux. This is a great thing for brown spirit.

Op has to understand that the water flow isn't how to control this type of still. He needs good water flow and a power controller to control the out put.

The rc will never be capable of controlling out put like a plated column or boka is capable of.

This needs to be run like a pot still or its dangerous

Adding a lieberg will make no difference if the water flow is insufficient. It's basically a pot still with a very small amount of reflux. This is a great thing for brown spirit.

Op has to understand that the water flow isn't how to control this type of still. He needs good water flow and a power controller to control the out put.

The rc will never be capable of controlling out put like a plated column or boka is capable of.

This needs to be run like a pot still or its dangerous

- coffe addict

- Posts: 1027

- Joined: Thu Feb 26, 2015 12:00 pm

- Location: Brisbane central

- equipment: 18 gal keg boiler on its side on wheel's with fill port, 1in drain and 2x2.4kw elements

4in 5 plate modular blockhead with optional infusion basket

Re: Reflux / Pot still

I think we all know a cm still is the poorest cousin of the lm,vm,cm families.

However, its what he has at the moment and I'm happy if we can help him get it to a safe and useful state of operation for what he wants to make.

While not as effective as a vm or lm, it does work! Not as well but it does.

I am surprised it gets too much reflux without any packing though. Thought it would run pretty well as a pot still?

Maybe run it with just enough water to knock down the vapour? The product will be hot and hard to read strength but reflux will be kept to a minimum and vapour will be kept under control. But I believe he tried that.

However, its what he has at the moment and I'm happy if we can help him get it to a safe and useful state of operation for what he wants to make.

While not as effective as a vm or lm, it does work! Not as well but it does.

I am surprised it gets too much reflux without any packing though. Thought it would run pretty well as a pot still?

Maybe run it with just enough water to knock down the vapour? The product will be hot and hard to read strength but reflux will be kept to a minimum and vapour will be kept under control. But I believe he tried that.

- warramungas

- Posts: 1436

- Joined: Sun Oct 18, 2015 9:38 pm

- Location: Nor Perth

- equipment: 180 litre fermenter x 2

30 liter boiler

PDA-1

2" four plate modular bubbler

2" one meter long LM column

110 liter boiler with 25 liter (max) inline thumper

4" x 4 plate bubble cap still

Re: Reflux / Pot still

Toadskin: i was referring to the current setup not your new condenser, the new condenser will work well, its a proven design.

What %ABV is your neutral coming out at?

Re-route your cooling lines to loop through the column and a sepatare loop for the PC, no need for flow control on the PC really unless you want to try and save water.

What %ABV is your neutral coming out at?

Re-route your cooling lines to loop through the column and a sepatare loop for the PC, no need for flow control on the PC really unless you want to try and save water.

- scythe

- Posts: 1860

- Joined: Thu Nov 14, 2013 6:34 am

- Location: Central West NSW

- equipment: Dreaming of a 4" bubbler

Re: Reflux / Pot still

When I'm running it as normal, to produce neutral, I get up around the 92 - 93% if I run it nice and slow.

Running as a pot still I was getting 50 - 60% but at an extremely low rate and it was obvious that most of the product was going into the atmosphere. (I could smell it out on the road) The product was really nice stuff though, very clear but with that real molasses nose to it. Running the water through the system, at the slowest rate, produced plenty of product at a higher ABV but lost most of the aroma. I don't know but maybe the molasses taste/aroma would develop more as it aged on oak as some guys describe.

Water run isn't a problem as I have a recirculating system through a 5000 litre rain water tank.

My thoughts were that if I could run the still as the pot still, but add extra condensing after the column, it would keep the reflux to the minimum but recover a lot of what I was losing to the atmosphere, hopefully resulting in more of the really nice stuff.

Running as a pot still I was getting 50 - 60% but at an extremely low rate and it was obvious that most of the product was going into the atmosphere. (I could smell it out on the road) The product was really nice stuff though, very clear but with that real molasses nose to it. Running the water through the system, at the slowest rate, produced plenty of product at a higher ABV but lost most of the aroma. I don't know but maybe the molasses taste/aroma would develop more as it aged on oak as some guys describe.

Water run isn't a problem as I have a recirculating system through a 5000 litre rain water tank.

My thoughts were that if I could run the still as the pot still, but add extra condensing after the column, it would keep the reflux to the minimum but recover a lot of what I was losing to the atmosphere, hopefully resulting in more of the really nice stuff.

- toadskin

- Posts: 41

- Joined: Sat Dec 01, 2012 1:22 pm

- Location: Geraldton WA

- equipment: Home made Reflux still with Liebig condenser and a home made 2" Pot Still with Liebig.

30 posts

• Page 1 of 2 • 1, 2

Who is online

Users browsing this forum: No registered users and 35 guests

5 Star Store

5 Star Store Community Guidelines

Community Guidelines Newbies Corner

Newbies Corner Recipes

Recipes AD search

AD search